| Width | 18” |

| Length | 42” |

| Thickness | 3” |

Standard Markings

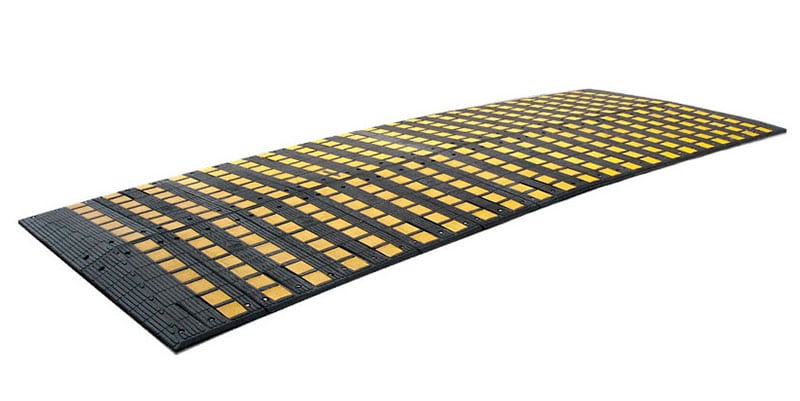

Rubber Humps for Traffic Calming

Our rubber speed humps are heavy duty and long-lasting yet offer easy removal for road resurfacing. They are simply bolted down to the road and can be removed and reinstalled whenever necessary. While they are a great way to improve road safety, traffic humps aren’t always the best choice on emergency response routes. For streets where response time is a concern, rubber speed cushions may be a better choice.

Speed humps should ideally be installed in a series to sustain their speed reduction effect. They are best placed mid-intersection. Made of interlocking units that simply snap together, Traffic Logix speed humps are quick and easy to install. Available in 3” or 4” heights and typically installed in 7’ or 14’ lengths, rubber humps are effective in slowing cars down. They offer maximum visibility, excellent durability, and are an excellent tool to reduce traffic speeds and return safety to neighborhood roads.

Features:

• Interlocking, puzzle piece design

• Highly visible with bright highway tape

• Environmentally friendly

• Quick and simple to install

• Customizable sizing & taping

Specs

Unit Specs

Speed Hump Specs

| Width | From 84” & up, by 18” increments |

| Length | From 72” & up, by 42” increments |

| Height | 3” or 4” |

Standard Speed Hump Specs

| Width | Varies |

| Length | 7’ or 14’ |

| Height | 3” or 4” |

| Warranty | 2 Years |

Physical Properties

| Material | 100% recycled synthetic and natural rubber composite |

| Tensile strength | Minimum 500 psi |

| Shore hardness | Minimum 70A |

| Specific gravity | 1.1 |

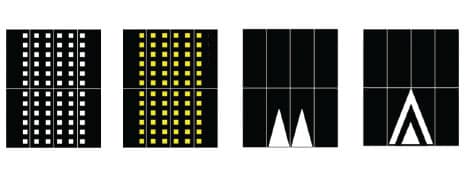

| Markings | Rubber modules are available in all black, black with yellow or white reflective square markings, or with white reflective arrow markings |

Speed Reduction

Speed Humps

Speed humps are also known as road humps or undulations. They are typically used in areas where the posted speed limit is under 30 mph, such as local streets or connector roads where smooth flowing traffic is ideal but speeding would endanger pedestrians. Speed humps are commonly used in school zones or near parks and playgrounds.

Speed humps usually span the entire lane that they are placed in so that a vehicle is forced to drive over them. A speed hump is mildly felt when a vehicle passes over it at the correct speed. If a vehicle is driving too fast, it can significantly jar the vehicle, creating a noticeably uncomfortable situation.

Speed humps are designed in many lengths and profiles. The size used will depend on the location, and the different designs will determine how much discomfort is experienced in the vehicle. They are usually placed in series to maintain speed control throughout a long corridor, and the travel length itself typically ranges from 3-20 feet.

Speed Bumps

Speed bumps are designed to be more aggressive and are used to reduce traffic to speeds between 2-10 mph. They are usually located in areas where vehicles and pedestrians are in closer proximity, such as parking lots or driveways. It is highly unusual to see a speed bump on a public road because they would seriously disrupt the flow of traffic. They can also damage vehicles that are traveling at otherwise normal road speeds.

Speed bumps are usually two to four inches in height, but they have a much shorter travel length than speed humps. Like speed humps, they are typically placed in series, at intervals, to maintain speed reduction. Speed bumps often create an intense bounce in the vehicle. Because of their smaller size, a vehicle driving over the speed limit would experience uncomfortable jolts.